The first discovery of PVC

Not so long ago we were quite used to traditional wooden frame windows and rather comfortable with them. But mankind has always been committed to finding better materials that will make our life easier and offer such benefits which natural products cannot offer.

PVC was one of the materials discoveries of which became an accidental occurrence and it had a long and hard path to go before it was able to get widely spread in industrial production.

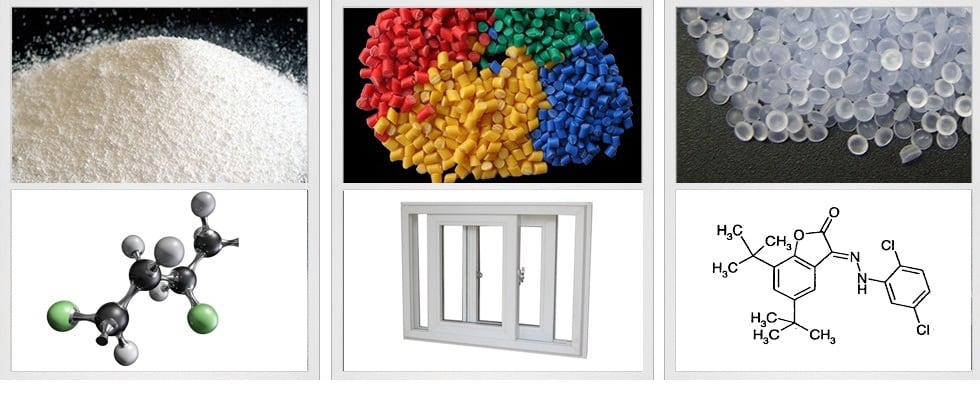

The first accidental discovery of PVC dates back to the 19th century, the years of 1838 and 1872 – experiments were done by French and German scientists led to the discovery of vinyl chloride gas which was accompanied by the appearance of the PVC in a white solid state. At that time no one managed to bring that material to the commercial level for the reason that it was very difficult to work with.

At the beginning of the 20th-century polymerization of vinyl chloride with sunlight was patented by a German inventor.

The really successful PVC experiments took place in the USA shortly after, when Waldo Semon, an American chemical engineer managed to synthesize the polymer having the goal to replace natural rubber. His method of plasticizing PVC by mixing it with different additives was patented and brought to us a flexible material that is easy to process and use commercially.

PVC applications

Five companies started mass production of PVC by the middle of the 20th century, and in the following decades found even more innovative uses in various industries.

PVC durability has been enhanced as well, thus leading towards applications in the construction industry.

PVC was becoming an essential and integral product of the building applications with all its beneficial properties such as resistance to light, corrosion and chemicals and even extreme temperatures.

At present PVC takes third place in production volume among other types of plastic in the world. Lots of industries including health care, transportation, textiles and clothing, construction etc. have been relying on this outstanding polymer which besides its excellent durability also has a low cost.

PVC in window making application

One of the most popular construction applications of PVC is plastic windows or uPVC windows. “u” means it is unplasticized, i.e. not softened by chemical plasticizers.

Being a mixture of chlorine, carbon and hydrogen, uPVC in its pure state is not very suitable for window profiles that is why some stabilizers are being added to it and then uPVC becomes perfect for window application.

If you have installed uPVC windows then you don’t need to worry about them being affected by weather, rotting, swelling or fading colour.

The lifespan of uPVC windows is considered to be about 25 years and then the material can be recycled at high temperature.

How uPVC windows are made

Modern uPVC windows by Northview Windows & Doors are made using the latest innovative technology of U-R-B-A-N machinery – one of the world’s best vinyl window production equipment.

Production of the uPVC window starts by putting molten uPVC into the precision die to form a profile. Each profile has its own design characteristics.

uPVC profiles are then cut into sections of the specific size which are joined together by means of heat fusion welding to form a window shape. Each profile has metal reinforcements inserted for extra strength and stability. Welded corners of uPVC profiles are then being cleaned by corner cleaning machines and profiles are being assembled into windows.

If you have any questions about how uPVC windows are made and how they function, please, feel free to ask our experts.

Leave A Comment

You must be logged in to post a comment.