Why Fiberglass?

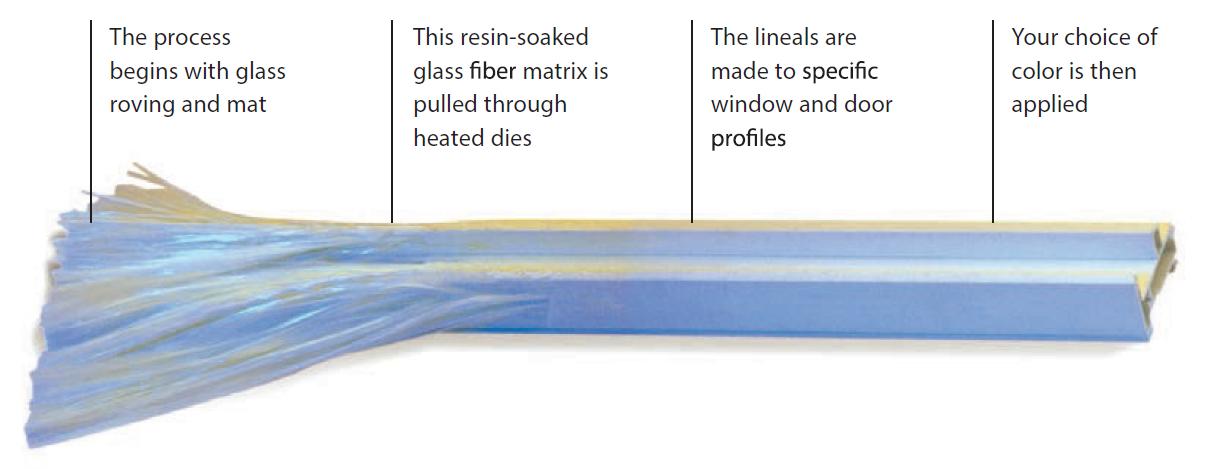

Pultruded fiberglass is an engineered material that is created through a process where strands of glass and glass matting are pulled through a heated die. The glass is bonded together with a matrix of “heat setting” resins as it passes through the die at extremely high temperatures. The resulting lineals (customized to specific window component requirements) are cut to length.

Pultruded fiberglass lineals have a finish topcoat applied “in-line” during the pultrusion process or “off-line” at a later stage to suit the color/finish required.

Consider the important factors and compare the advantages of Pultruded Fiberglass:

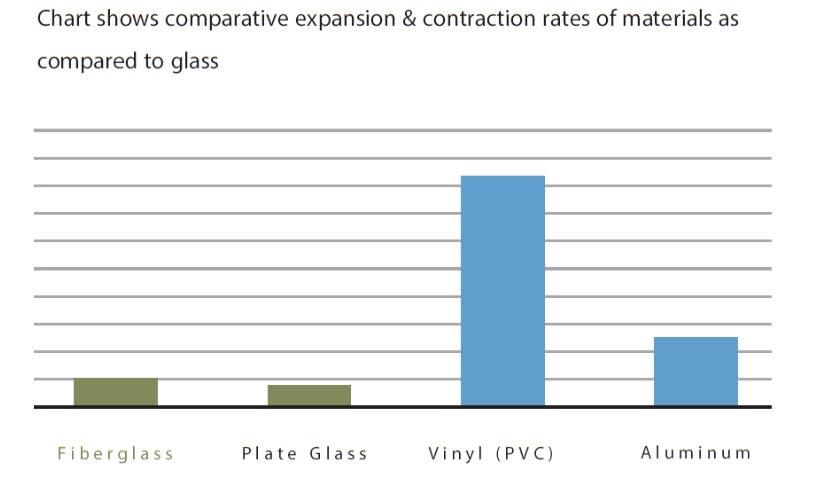

STABILITY – Fiberglass provides an extremely low rate of expansion/contraction in the face of heat or cold. It expands and contracts an incredible 800% less than vinyl.

CONDUCTIVITY – Fiberglass combines strength with very low levels of conductivity, without adding thermal breaks. Fiberglass is amazingly less conductive than aluminum and FG frames.

STRENGTH – a well engineered FG window delivers vastly superior strength characteristics when compared to other windows like PVC. FG provides greater sheer strength when compared to PVC.

LOW MAINTENANCE – Fiberglass is the most stable material which provides an ideal base for a full range of nishes, ensuring an unbelievably durable window. This material is so tough that it will withstand extremes from Arctic cold to blazing desert heat or the rugged seacoast!

ENVIRONMENTALLY FRIENDLY – Fiberglass not only features the lowest embodied energy (low energy consumption in lineal production) when compared to other common window frame materials but also provides the longest life expectancy. This has led experts to recognize FG as the most environmentally friendly window product.

NON-CORRODING – Fiberglass material is used in boats and bridge structures which face punishing loads and stresses as well as corrosive materials such as salt water. FG frames provide superior life and durability as compared to vinyl and aluminum in corrosive/coastal environments.

D U R A B I L I T Y – In the latest **Life cycle assessment of windows for the North American residential market, the findings stated Fiberglass windows have 38% longer useful life expectancy than vinyl. The comparison used an Inline fiberglass window. Other fiberglass companies refer to the results, though should have their products tested before making the same claim.